Catalog

CAD (0)

▾

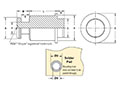

PEM® surface mounted standoffs that eliminate the need for attaching screws

PEM® SMTSK™ standoffs are designed so that a PC board or panel can be quickly slipped into place and then removed from an assembly by simply sliding the board sideways and lifting it off. These standoffs mount on PC Boards in the same manner and at the same time as other surface mount components prior to the automated reflow solder process.

Reduces scrap, handling and risk of board damage.

Unique barrel design allows for quick attachment and detachment.

Makes horizontal or vertical component mounting possible.

Provided on tape and reel compatible with existing SMT automated installation equipment.

PEM® SMTSK™ standoffs are designed so that a PC board or panel can be quickly slipped into place and then removed from an assembly by simply sliding the board sideways and lifting it off. These standoffs mount on PC Boards in the same manner and at the same time as other surface mount components prior to the automated reflow solder process.

Unit of Measure

- 1 Packaged on 13" recyclable reels. Tape width is 24mm and 16mm. Pitch is 16mm and 12mm. Reels conform to EIA-481.

-

2 (1) See PEM® Technical Support section of our website for related plating standards and specifications.

(2) Optimal solderability life noted on package.

(3) The tin deposit on SMTSK standoffs meet the requirements of ASTM B545, Class A and although the copper and nickel barrier layers used under the tin do not strictly comply with ASTM B545 thickness requirements they have proven effective at preventing zinc migration and providing the specified solderable shelf life.