Catalog

CAD (0)

▾

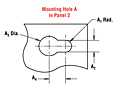

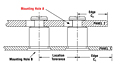

PEM® KEYHOLE® Standoffs and sheet joining fasteners are designed so that a PC board or panel can be quickly slipped

into place and then removed from an assembly by simply sliding the board sideways and lifting it off. These standoffs

and fasteners can save valuable time and dramatically reduce the amount of loose hardware required.

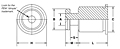

SKCF™ standoffs can be used for spacing or mounting of replaceable components. Typically, several standoffs are used with one standard PEM® threaded standoff which accepts a screw to secure the board or component against any unwanted movement.

SKCF™ standoffs can be used for spacing or mounting of replaceable components. Typically, several standoffs are used with one standard PEM® threaded standoff which accepts a screw to secure the board or component against any unwanted movement.

- Allow detachable spacing of two sheets

- Clinch feature mounts fastener permanently and flush into metal sheet

- Unique barrel design allows for quick attachment and detachment

- Makes horizontal or vertical component mounting possible

Unit of Measure

- 1 HRB - Hardness Rockwell “B” Scale. HB - Hardness Brinell.