Catalog

CAD (0)

▾

Floating Self-Clinching Fasteners A4, AS, AC - Unified

Floating self-clinching fasteners A4, AS, AC

Locking and Non-locking Threads

These fasteners provide load-bearing threads in thin sheets and permit up to .030” adjustment for mating hole misalignment.

The self-clinching feature offers fast and simple assembly. The fasteners are squeezed into prepared holes using any standard press. The sheet remains flush on one side, and the fastener is permanently locked in place.

Extra strength and support in assembly is obtained by the threads of the floating nut extending fully into the retainer shank (a unique PEM feature). A self-locking version of the fastener is also offered. Thread locking torque performance is equivalent to applicable NASM25027 specifications.

Non-locking Type A4 and self-locking Type LA4 fasteners provide load-bearing threads in stainless steel sheets as thin as .038” with hardness up to HRB 88 on the Rockwell “B” scale.

Many PEM Type AS and AC self-clinching floating fasteners correspond to sizes in US NASM45938/11 specifications. Check our web site for a complete Military Specification and National Aerospace Standards Reference Guide (Bulletin NASM).

These fasteners provide load-bearing threads in thin sheets and permit up to .030” adjustment for mating hole misalignment.

The self-clinching feature offers fast and simple assembly. The fasteners are squeezed into prepared holes using any standard press. The sheet remains flush on one side, and the fastener is permanently locked in place.

Extra strength and support in assembly is obtained by the threads of the floating nut extending fully into the retainer shank (a unique PEM feature). A self-locking version of the fastener is also offered. Thread locking torque performance is equivalent to applicable NASM25027 specifications.

Non-locking Type A4 and self-locking Type LA4 fasteners provide load-bearing threads in stainless steel sheets as thin as .038” with hardness up to HRB 88 on the Rockwell “B” scale.

Many PEM Type AS and AC self-clinching floating fasteners correspond to sizes in US NASM45938/11 specifications. Check our web site for a complete Military Specification and National Aerospace Standards Reference Guide (Bulletin NASM).

Unit of Measure

| Items |

AS-440-1ZI Floating Self-Clinching Fasteners A4, AS, AC - Unified |

AS-632-1ZI Floating Self-Clinching Fasteners A4, AS, AC - Unified |

AS-832-1ZI Floating Self-Clinching Fasteners A4, AS, AC - Unified |

AS-024-1ZI Floating Self-Clinching Fasteners A4, AS, AC - Unified |

AS-032-1ZI Floating Self-Clinching Fasteners A4, AS, AC - Unified |

|||||

| Thread Size | N/A .112-40 (#4-40) | N/A .138-32 (#6-32) | N/A .164-32 (#8-32) | N/A .190-24 (#10-24) | N/A .190-32 (#10-32) | |||||

| Thread Type |

N/A

Non-Locking

|

|||||||||

| Thread Code | N/A 440 | N/A 632 | N/A 832 | N/A 024 | N/A 032 | |||||

| Shank Code | N/A 1 | |||||||||

|

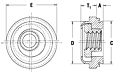

A (Shank) Max. |

N/A

0.038 in

|

|||||||||

| Min. Sheet Thickness | N/A .038 in | |||||||||

| Hole Size in Sheet + .003 - .000 | N/A .290 in | N/A .328 in | N/A .368 in | N/A .406 in | N/A .406 in | |||||

| C Max. | N/A .289 in | N/A .327 in | N/A .367 in | N/A .405 in | N/A .405 in | |||||

| D Max. | N/A .290 in | N/A .335 in | N/A .365 in | N/A .405 in | N/A .405 in | |||||

| E ± .015 | N/A .360 in | N/A .390 in | N/A .440 in | N/A .470 in | N/A .470 in | |||||

| T1 Max. | N/A .130 in | N/A .130 in | N/A .130 in | N/A .170 in | N/A .170 in | |||||

| Min. Dist. Hole C/L to Edge | N/A .300 in | N/A .320 in | N/A .34 in | N/A .360 in | N/A .360 in | |||||

| Float | N/A .015” minimum, in all directions from center, .030” total | |||||||||

| Fastener Material | N/A Steel | |||||||||

| Fastener Materials - Retainer | N/A Heat-Treated Carbon Steel | |||||||||

| Fastener Materials - Nut | N/A Carbon Steel | |||||||||

| Standard Finish - Retainer & Nut | N/A Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless | |||||||||

| For Use in Sheet Hardness1 | N/A HRB 70 / HB 125 or Less | |||||||||

| Thread Specification | N/A Internal, ANSI B1.1, 2B | |||||||||

| CAD Supplier | N/A PennEngineering® (PEM®) | |||||||||

|

||||||||||