Catalog

CAD (0)

▾

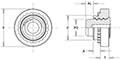

PEM® PreTect™ Thread Masking Plugs

Nuts – Types S, SS, CLS, CLSS, CLA, SP

PEM® PreTect™ Thread Masking Plugs reduce labor and protect threads from paint and powder coating processes. PreTect TMthread maskind plugs are avaible for standard type self-clinching nuts in variety of thread sizes and materials.

Features include:

- Fasteners are shipped with plugs already in place.

- Plugs easily removed by end user with fine tip tool.

- Plugs can withstand 482°F/250°C temperatures

Unit of Measure

| Items |

S-440-0ZI-TP PEM® PreTect™ Thread Masking Plugs |

S-632-0ZI-TP PEM® PreTect™ Thread Masking Plugs |

S-832-0ZI-TP PEM® PreTect™ Thread Masking Plugs |

S-0420-0ZI-TP PEM® PreTect™ Thread Masking Plugs |

S-440-1ZI-TP PEM® PreTect™ Thread Masking Plugs |

|||||

| Description |

N/A

PEM® PreTect™ Thread Masking Plugs reduce labor and protect threads from paint and powder coating processes. PreTect™ Thread Masking Plugs are available for standard type self-clinching nuts in variety of thread sizes and materials. Features include:

|

|||||||||

| Thread Size | N/A .112-40 (#4-40) | N/A .138-32 (#6-32) | N/A .164-32 (#8-32) | N/A .250-20 (1/4-20) | N/A .112-40 (#4-40) | |||||

| Thread Code | N/A 440 | N/A 632 | N/A 832 | N/A 0420 | N/A 440 | |||||

| Shank Code | N/A 0 | N/A 0 | N/A 0 | N/A 0 | N/A 1 | |||||

|

A (Shank) Max. |

N/A

.030 in

|

N/A

.030 in

|

N/A

.030 in

|

N/A

.045 in

|

N/A

0.038 in

|

|||||

| Plug Material | N/A Black Silicone Rubber | |||||||||

| Plug High Temperature Resistant | N/A 482 ºF250 ºC | |||||||||

| Plug Hardness | N/A Shore a 70 | |||||||||

| Rec. Min. Sheet Thickness1 | N/A .030 in | N/A .030 in | N/A .030 in | N/A .047 in | N/A .040 in | |||||

| Hole Size in Sheet + .003 - .000 | N/A .166 in | N/A .1875 in | N/A .213 in | N/A .344 in | N/A .166 in | |||||

| C Max. | N/A .165 in | N/A .187 in | N/A .212 in | N/A .343 in | N/A .165 in | |||||

| E ± .010 | N/A .250 in | N/A .280 in | N/A .310 in | N/A .440 in | N/A .250 in | |||||

| T ± .010 | N/A .070 in | N/A .070 in | N/A .090 in | N/A .170 in | N/A .070 in | |||||

| PD | N/A 0.098 in | N/A 0.122 in | N/A 0.147 in | N/A 0.216 in | N/A 0.098 in | |||||

| PL | N/A 0.0615 in | N/A 0.0615 in | N/A 0.0612 in | N/A 0.0764 in | N/A 0.0535 in | |||||

| Min. Dist. Hole C/L to Edge2 | N/A .19 in | N/A .22 in | N/A .27 in | N/A .34 in | N/A .19 in | |||||

| For Use in Sheet Hardness3 | N/A HRB 80 / HB 150 or Less | |||||||||

| Thread Specification | N/A Internal, ASME B1.1, 2B | |||||||||

| Fastener Material | N/A Heat-Treated Carbon Steel | |||||||||

| Standard Finish | N/A Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless | |||||||||

| Optional Finish | N/A | |||||||||

| CAD Supplier | N/A PennEngineering® (PEM®) | |||||||||

|

||||||||||