Catalog

CAD (0)

▾

SELF-CLINCHING KEYHOLE® FASTENERS - HSKS-R™ - Unified

Panel to Panel, KEYHOLE® Style – Types HSKS-R

PEM® KEYHOLE® Standoffs and sheet joining fasteners are designed so that a PC board or panel can be quickly slipped

into place and then removed from an assembly by simply sliding the board sideways and lifting it off. These standoffs

and fasteners can save valuable time and dramatically reduce the amount of loose hardware required.

Type SKS-R™ fasteners are designed so that two sheets can be quickly joined flat against each other. Typically, several fasteners are used with one standard PEM® threaded F™ flush nut which accepts a screw to secure the sheets against any unwanted movement.

Type SKS-R™ fasteners are designed so that two sheets can be quickly joined flat against each other. Typically, several fasteners are used with one standard PEM® threaded F™ flush nut which accepts a screw to secure the sheets against any unwanted movement.

- Allow detachable spacing of two sheets

- Clinch feature mounts fastener permanently and flush or sub-flush into metal sheet

- Unique barrel design allows for quick “panel-on-panel” attachment and detachment

- Can be clinched into blind hole where concealed head is required

- Makes horizontal or vertical component mounting possible

- SKS-R™ fasteners are designed to provide high side-load in verticle component mounting applications

- SKS-R™ fasteners are available for various top sheet thicknesses and hole sizes

Unit of Measure

| Items |

HSKS-R1.5-2.5-ZI SELF-CLINCHING KEYHOLE® FASTENERS - HSKS-R™ - Unified |

HSKS-R1.5-3.2-ZI SELF-CLINCHING KEYHOLE® FASTENERS - HSKS-R™ - Unified |

HSKS-R1.5-4.0-ZI SELF-CLINCHING KEYHOLE® FASTENERS - HSKS-R™ - Unified |

HSKS-R2.0-2.5-ZI SELF-CLINCHING KEYHOLE® FASTENERS - HSKS-R™ - Unified |

HSKS-R2.0-3.2-ZI SELF-CLINCHING KEYHOLE® FASTENERS - HSKS-R™ - Unified |

|||||

| Panel 1 (Bottom) Thickness Range | N/A .047 to .055 in | |||||||||

| Panel 1 (Bottom) Mounting Hole B + .003 - .000 | N/A .237 in | N/A .277 in | N/A .316 in | N/A .237 in | N/A .277 in | |||||

| Panel 2 (Top) Sheet Thickness Max. | N/A .060 in | N/A .060 in | N/A .060 in | N/A .080 in | N/A .080 in | |||||

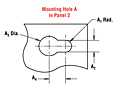

| Panel 2 (Top) Mounting Hole A1 Nom. | N/A .059 in | N/A .073 in | N/A .089 in | N/A .059 in | N/A .073 in | |||||

| Panel 2 (Top) Mounting Hole A2 ± .003 | N/A .118 in | N/A .146 in | N/A .177 in | N/A .118 in | N/A .146 in | |||||

| Panel 2 (Top) Mounting Hole A3 ± .003 | N/A .197 in | N/A .236 in | N/A .276 in | N/A .197 in | N/A .236 in | |||||

| Panel 2 (Top) Mounting Hole A4 Min. |

N/A

.148 in

|

N/A

.181 in

|

N/A

.217 in

|

N/A

.148 in

|

N/A

.181 in

|

|||||

| Panel 1 (Bottom) Sheet Hardness Max.1 | N/A HRB 80 / HB 150 | |||||||||

| Panel 2 (Top) Material | N/A Any | |||||||||

|

A Max. |

N/A

.047 in

|

|||||||||

| B ± .003 | N/A .177 in | N/A .217 in | N/A .256 in | N/A .177 in | N/A .217 in | |||||

| C Max. | N/A .236 in | N/A .276 in | N/A .315 in | N/A .236 in | N/A .276 in | |||||

| D Anvil Hole + .003 - .000 | N/A .183 in | N/A .222 in | N/A .262 in | N/A .183 in | N/A .222 in | |||||

| H Nom. | N/A .276 in | N/A .315 in | N/A .354 in | N/A .276 in | N/A .315 in | |||||

| M Max. | N/A .156 in | N/A .156 in | N/A .156 in | N/A .175 in | N/A .175 in | |||||

| N ± .003 | N/A .099 in | N/A .126 in | N/A .157 in | N/A .099 in | N/A .126 in | |||||

| S ± .003 | N/A .115 in | N/A .115 in | N/A .115 in | N/A .135 in | N/A .135 in | |||||

| Panel 1 (Bottom) Edge Distance C1 Min. |

N/A

.276 in

|

N/A

.295 in

|

N/A

.315 in

|

N/A

.276 in

|

N/A

.295 in

|

|||||

| Panel 1 (Bottom) Location Tolerance Max. | N/A ±.005 in | |||||||||

| Panel 2 (Top) Edge Distance C2 Min. | N/A .160 in | N/A .201 in | N/A .240 in | N/A .160 in | N/A .201 in | |||||

| Standard Material | N/A Hardened Steel | |||||||||

| Standard Finish2 | N/A Zinc Plated per ASTM B633, SC1 (5um) Type III, Colorless | |||||||||

| CAD Supplier | N/A PennEngineering® (PEM®) | |||||||||

|

||||||||||