| Items |

S-RTM6-00ZI

All Metal, RT® Free-Running Locknuts - Metric

|

S-RTM3-0ZI

All Metal, RT® Free-Running Locknuts - Metric

|

S-RTM4-0ZI

All Metal, RT® Free-Running Locknuts - Metric

|

SS-RTM5-0ZI

All Metal, RT® Free-Running Locknuts - Metric

|

S-RTM6-0ZI

All Metal, RT® Free-Running Locknuts - Metric

|

|

Description

|

N/A

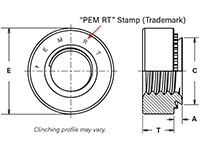

PEM® S-RT™ free-running locknuts are free-running until clamp load is induced. A modified thread angle on the loaded flank provides the vibration resistant locking feature.

- Screw turns freely until a clamp load is applied.

- Resistant to vibrational loosening.

- Back side of panel is flush or sub-flush for screw installation.

- Locking feature reusability is not affected by number of on/off cycles.

- Uses same mounting hole and installation tooling as standard S™ nut fasteners

found in PEM® Bulletin CL.

|

|

Thread Size x Pitch

|

N/A

M6 x 1

|

N/A

M3 x 0.5

|

N/A

M4 x 0.7

|

N/A

M5 x 0.8

|

N/A

M6 x 1

|

|

Thread Code

|

N/A

RTM6

|

N/A

RTM3

|

N/A

RTM4

|

N/A

RTM5

|

N/A

RTM6

|

|

Shank Code

|

N/A

0

|

|

A (Shank) Max.

|

N/A

0.89 mm

|

N/A

0.77 mm

|

N/A

0.77 mm

|

N/A

0.77 mm

|

N/A

1.15 mm

|

|

Rec. Min. Sheet Thickness1

|

N/A

0.92 mm

|

N/A

0.8 mm

|

N/A

0.8 mm

|

N/A

0.8 mm

|

N/A

1.2 mm

|

|

Hole Size in Sheet + 0.08

|

N/A

8.75 mm

|

N/A

4.22 mm

|

N/A

5.41 mm

|

N/A

6.35 mm

|

N/A

8.75 mm

|

|

C Max.

|

N/A

8.73 mm

|

N/A

4.20 mm

|

N/A

5.38 mm

|

N/A

6.33 mm

|

N/A

8.73 mm

|

|

E ± 0.25

|

N/A

11.18 mm

|

N/A

6.35 mm

|

N/A

7.87 mm

|

N/A

8.64 mm

|

N/A

11.18 mm

|

|

T ± 0.25

|

N/A

4.08 mm

|

N/A

1.50 mm

|

N/A

2.00 mm

|

N/A

2.00 mm

|

N/A

4.08 mm

|

|

Min. Dist. Hole C/L to Edge

|

N/A

8.6 mm

|

N/A

4.8 mm

|

N/A

6.9 mm

|

N/A

7.10 mm

|

N/A

8.6 mm

|

|

For Use in Sheet Hardness

|

N/A

HRB 80 / HB 150 or Less

|

|

Thread Specification

|

N/A

Modified thread form on loaded flank. Will accept a maximum material 6g screw.

|

|

Fastener Material

|

N/A

Hardened Carbon Steel

|

|

Standard Finish

|

N/A

Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless

|

|

Optional Finish

|

N/A

|

|

CAD Supplier

|

N/A

PennEngineering® (PEM®)

|