| Items |

CLA-256-1

Self-Clinching Nuts - Type CLA - Unified

|

CLA-440-1

Self-Clinching Nuts - Type CLA - Unified

|

CLA-632-1

Self-Clinching Nuts - Type CLA - Unified

|

CLA-832-1

Self-Clinching Nuts - Type CLA - Unified

|

CLA-024-1

Self-Clinching Nuts - Type CLA - Unified

|

|

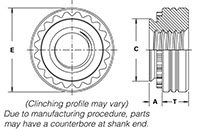

Description

|

N/A

Type CLA aluminum nuts are recommended for use in aluminum sheet with a hardness of HRB 50 or less on the Rockwell “B” scale.

Unplated threads are sized to accept a basic go gauge after .00025” plating.

|

|

Thread Size

|

N/A

.086-56 (#2-56)

|

N/A

.112-40 (#4-40)

|

N/A

.138-32 (#6-32)

|

N/A

.164-32 (#8-32)

|

N/A

.190-24 (#10-24)

|

|

Thread Code

|

N/A

256

|

N/A

440

|

N/A

632

|

N/A

832

|

N/A

024

|

|

Shank Code

|

N/A

1

|

|

A (Shank) Max.

|

N/A

0.038 in

|

|

Min. Sheet Thickness1

|

N/A

.040 in

|

|

Hole Size in Sheet + .003 - .000

|

N/A

.166 in

|

N/A

.1875 in

|

N/A

.213 in

|

N/A

.234 in

|

N/A

.296 in

|

|

C Max.

|

N/A

.165 in

|

N/A

.187 in

|

N/A

.212 in

|

N/A

.233 in

|

N/A

.295 in

|

|

E ± .010

|

N/A

.250 in

|

N/A

.250 in

|

N/A

.280 in

|

N/A

.310 in

|

N/A

.370 in

|

|

T ± .010

|

N/A

.070 in

|

N/A

.090 in

|

N/A

.090 in

|

N/A

.130 in

|

N/A

.160 in

|

|

Min. Dist. Hole C/L to Edge2

|

N/A

.19 in

|

N/A

.22 in

|

N/A

.27 in

|

N/A

.28 in

|

N/A

.310 in

|

|

For Use in Sheet Hardness3

|

N/A

HRB 50 / HB 82 or less

|

|

Thread Specification

|

N/A

Internal, ASME B1.1, 2B

|

|

Fastener Material

|

N/A

Aluminum

|

|

Standard Finish

|

N/A

None

|

|

CAD Supplier

|

N/A

PennEngineering® (PEM®)

|