| Items |

SP-440-0

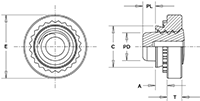

Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified

|

SP-632-0

Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified

|

SP-832-0

Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified

|

SP-032-0

Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified

|

SP-0420-0

Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified

|

|

Description

|

N/A

Type SP, PEM 300® nuts provide strong load-bearing threads in stainless steel sheets as thin as .030”.

Type SP is recommended for use in stainless steel sheets HRB (Rockwell "B" scale) 90 or less and HB (Hardness Brinell) 185 or less.

|

|

Thread Size

|

N/A

.112-40 (#4-40)

|

N/A

.138-32 (#6-32)

|

N/A

.164-32 (#8-32)

|

N/A

.190-32 (#10-32)

|

N/A

.250-20 (1/4-20)

|

|

Thread Code

|

N/A

440

|

N/A

632

|

N/A

832

|

N/A

032

|

N/A

0420

|

|

Shank Code

|

N/A

0

|

|

A (Shank) Max.

|

N/A

.030 in

|

N/A

.030 in

|

N/A

.030 in

|

N/A

.030 in

|

N/A

.045 in

|

|

Rec. Min. Sheet Thickness1

|

N/A

.030 in

|

N/A

.030 in

|

N/A

.030 in

|

N/A

.030 in

|

N/A

.047 in

|

|

Hole Size in Sheet + .003 - .000

|

N/A

.166 in

|

N/A

.1875 in

|

N/A

.213 in

|

N/A

.250 in

|

N/A

.344 in

|

|

C Max.

|

N/A

.165 in

|

N/A

.187 in

|

N/A

.212 in

|

N/A

.249 in

|

N/A

.343 in

|

|

E ± .010

|

N/A

.250 in

|

N/A

.280 in

|

N/A

.310 in

|

N/A

.340 in

|

N/A

.440 in

|

|

T ± .010

|

N/A

.070 in

|

N/A

.070 in

|

N/A

.090 in

|

N/A

.090 in

|

N/A

.170 in

|

|

Min. Dist. Hole C/L to Edge2

|

N/A

.19 in

|

N/A

.22 in

|

N/A

.27 in

|

N/A

.28 in

|

N/A

.34 in

|

|

For Use in Sheet Hardness3

|

N/A

HRB 90 / HB 185 or Less

|

|

Thread Specification

|

N/A

Internal, ASME B1.1, 2B

|

|

Fastener Material

|

N/A

Age Hardened A286 Stainless Steel

|

|

Standard Finish

|

N/A

Passivated and/or Tested Per ASTM A380

|

|

CAD Supplier

|

N/A

PennEngineering® (PEM®)

|