CAD (0)

▾

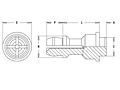

PEM® surface mounted standoffs that eliminate the need for attaching screws

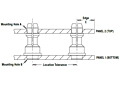

PEM® SMTSS™ fasteners feature a spring action to hold a P.C. Board securely without screw or threaded hardware, allowing for quick assembly.

Mount on P.C. Boards in the same manner and at the same time as other surface mount components prior to the automated reflow solder process.

Alleviated concerns about potential damage to P.C. Boards due to improper secondary installation operations.

Fasteners provided on tape and reel compatible with existing SMT automated installation equipment.

Benefits include reduced scrap, reduced handling and reduced risk of board damage.

Unit of Measure

- 1 Packaged on 330mm recyclable reels. Tape width is 24 mm. Supplied with polyimide patch for vacuum pick up. Reels conform to EIA-481.

- 2 (1) See PEM Technical Support section of our web site for related plating standards and specifications. (2) Optimal solderability life noted on packaging.