| Items |

TS4-10-025

Type TS™ Self-clinching microPEM® TackScrew ™

|

TS4-10-050

Type TS™ Self-clinching microPEM® TackScrew ™

|

|

Fastener Material

|

N/A

Heat-treated 400 Series Stainless Steel

|

|

Base Panel Hole Size Code

|

N/A

10

|

|

Top Sheet Thickness Code

|

N/A

025

|

N/A

050

|

|

Top Sheet Thickness

|

N/A

0.2 to 0.28 mm.008 to .011 in

|

N/A

0.48 to 0.56 mm.019 to .022 in

|

|

Base Panel Min. Sheet Thickness1

|

N/A

0.91 mm.036 in

|

|

Top Sheet Hole Size ±0.05mm/ ±.002in

|

N/A

1.47 mm.058 in

|

|

Base Panel Hole Size ±0.025mm/ ±.001in

|

N/A

0.99 mm.039 in

|

|

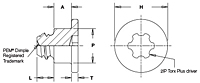

A ± 0.05mm/±.002in

|

N/A

0.406 mm.016 in

|

N/A

0.686 mm.027 in

|

|

H ± 0.1mm/±.004in

|

N/A

2 mm.079 in

|

|

L ± 0.1mm/±.004in

|

N/A

0.64 mm.025 in

|

|

P ± 0.05mm/±.002in

|

N/A

1.3 mm.051 in

|

|

T ± 0.1mm/±.004in

|

N/A

0.25 mm.010 in

|

|

Min. Dist. Hole C/L to Edge

|

N/A

1 mm.039 in

|

|

Standard Finish

|

N/A

Passivated and/or Tested Per ASTM A380

|

|

For Use in Sheet Hardness

|

N/A

HRB 89 or less (Hardness Rockwell “B” scale)

HB 187 or less (Hardness Brinell)

|

|

CAD Supplier

|

N/A

PennEngineering® (PEM®)

|