| Items |

PL-440-ZI

Nylon Insert Self-Locking Fasteners - Types PL and PLC - Unified

|

PL-632-ZI

Nylon Insert Self-Locking Fasteners - Types PL and PLC - Unified

|

PL-832-ZI

Nylon Insert Self-Locking Fasteners - Types PL and PLC - Unified

|

PL-032-ZI

Nylon Insert Self-Locking Fasteners - Types PL and PLC - Unified

|

PL-440-ZC

Nylon Insert Self-Locking Fasteners - Types PL and PLC - Unified

|

|

Thread Size

|

N/A

.112-40 (#4-40)

|

N/A

.138-32 (#6-32)

|

N/A

.164-32 (#8-32)

|

N/A

.190-32 (#10-32)

|

N/A

.112-40 (#4-40)

|

|

Thread Code

|

N/A

440

|

N/A

632

|

N/A

832

|

N/A

032

|

N/A

440

|

|

Material Code

|

N/A

|

|

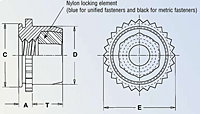

A (Shank) Max.

|

N/A

.060 in

|

|

Sheet Thickness1

|

N/A

.040 to .070 in

|

|

Hole Size in Sheet + .003 - .000

|

N/A

.234 in

|

N/A

.265 in

|

N/A

.297 in

|

N/A

.312 in

|

N/A

.234 in

|

|

C Max.

|

N/A

.233 in

|

N/A

.264 in

|

N/A

.296 in

|

N/A

.311 in

|

N/A

.233 in

|

|

D Max.

|

N/A

.215 in

|

N/A

.246 in

|

N/A

.278 in

|

N/A

.293 in

|

N/A

.215 in

|

|

E Max.

|

N/A

.274 in

|

N/A

.305 in

|

N/A

.338 in

|

N/A

.353 in

|

N/A

.274 in

|

|

T Max.

|

N/A

.130 in

|

N/A

.130 in

|

N/A

.155 in

|

N/A

.165 in

|

N/A

.130 in

|

|

Min. Dist. Hole C/L to Edge

|

N/A

.170 in

|

N/A

.19 in

|

N/A

.22 in

|

N/A

.250 in

|

N/A

.170 in

|

|

Max. Hole in Attached Parts

|

N/A

.132 in

|

N/A

.158 in

|

N/A

.184 in

|

N/A

.210 in

|

N/A

.132 in

|

|

Fastener Materials - Locking Element

|

N/A

Blue Nylon

|

|

For Use in Sheet Hardness2

|

N/A

HRB 70 / HB 125 or Less

|

|

Thread Specification

|

N/A

Internal, ANSI B1.1, 2B

|

|

Fastener Material

|

N/A

Heat-Treated Carbon Steel

|

|

Standard Finish

|

N/A

Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless

|

N/A

Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless

|

N/A

Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless

|

N/A

Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless

|

N/A

|

|

Optional Finish

|

N/A

|

N/A

|

N/A

|

N/A

|

N/A

Zinc plated per ASTM B633, SC1 (5µm), Type II, yellow

|

|

CAD Supplier

|

N/A

PennEngineering® (PEM®)

|