| Items |

SKS-R1.5-2.5-ZI

KEYHOLE® Sheet Joining Fasteners Type SKS-R™ - Metric

|

SKS-R1.5-3.2-ZI

KEYHOLE® Sheet Joining Fasteners Type SKS-R™ - Metric

|

SKS-R1.5-4.0-ZI

KEYHOLE® Sheet Joining Fasteners Type SKS-R™ - Metric

|

SKS-R2.0-2.5-ZI

KEYHOLE® Sheet Joining Fasteners Type SKS-R™ - Metric

|

SKS-R2.0-3.2-ZI

KEYHOLE® Sheet Joining Fasteners Type SKS-R™ - Metric

|

|

Panel 1 (Bottom) Thickness Range

|

N/A

1 to 1.19 mm

|

|

Panel 1 (Bottom) Mounting Hole B + 0.08

|

N/A

5.41 mm

|

N/A

6.00 mm

|

N/A

7.00 mm

|

N/A

5.41 mm

|

N/A

6.00 mm

|

|

Panel 2 (Top) Sheet Thickness Max.

|

N/A

1.54 mm

|

N/A

1.54 mm

|

N/A

1.54 mm

|

N/A

2.04 mm

|

N/A

2.04 mm

|

|

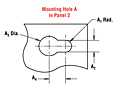

Panel 2 (Top) Mounting Hole A1 Nom.

|

N/A

1.5 mm

|

N/A

1.85 mm

|

N/A

2.25 mm

|

N/A

1.5 mm

|

N/A

1.85 mm

|

|

Panel 2 (Top) Mounting Hole A2 ± 0.08

|

N/A

3 mm

|

N/A

3.7 mm

|

N/A

4.5 mm

|

N/A

3 mm

|

N/A

3.7 mm

|

|

Panel 2 (Top) Mounting Hole A3 ± 0.08

|

N/A

5 mm

|

N/A

6 mm

|

N/A

7 mm

|

N/A

5 mm

|

N/A

6 mm

|

|

Panel 2 (Top) Mounting Hole A4 Min.

|

N/A

3.75 mm

|

N/A

4.6 mm

|

N/A

5.5 mm

|

N/A

3.75 mm

|

N/A

4.6 mm

|

|

Panel 1 (Bottom) Sheet Hardness Max.1

|

N/A

HRB 80 / HB 150

|

|

Panel 2 (Top) Material

|

N/A

Any

|

|

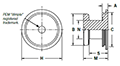

A Max.

|

N/A

1.00 mm

|

|

B ± 0.08

|

N/A

4.5 mm

|

N/A

5.5 mm

|

N/A

6.5 mm

|

N/A

4.5 mm

|

N/A

5.5 mm

|

|

C Max.

|

N/A

5.39 mm

|

N/A

5.98 mm

|

N/A

6.98 mm

|

N/A

5.39 mm

|

N/A

5.98 mm

|

|

D Anvil Hole + 0.08

|

N/A

4.65 mm

|

N/A

5.65 mm

|

N/A

6.65 mm

|

N/A

4.65 mm

|

N/A

5.65 mm

|

|

H Nom.

|

N/A

6.00 mm

|

N/A

7 mm

|

N/A

7.8 mm

|

N/A

6.00 mm

|

N/A

7 mm

|

|

M Max.

|

N/A

3.75 mm

|

N/A

3.75 mm

|

N/A

3.75 mm

|

N/A

4.25 mm

|

N/A

4.25 mm

|

|

N ± 0.08

|

N/A

2.5 mm

|

N/A

3.2 mm

|

N/A

4 mm

|

N/A

2.5 mm

|

N/A

3.2 mm

|

|

S ± 0.08

|

N/A

2.73 mm

|

N/A

2.73 mm

|

N/A

2.73 mm

|

N/A

3.23 mm

|

N/A

3.23 mm

|

|

Panel 1 (Bottom) Edge Distance C1 Min.

|

N/A

6 mm

|

|

Panel 1 (Bottom) Location Tolerance Max.

|

N/A

±.130 mm

|

|

Panel 2 (Top) Edge Distance C2 Min.

|

N/A

4.1 mm

|

N/A

5.1 mm

|

N/A

6.1 mm

|

N/A

4.1 mm

|

N/A

5.1 mm

|

|

Standard Material

|

N/A

Hardened Steel

|

|

Standard Finish2

|

N/A

Zinc Plated per ASTM B633, SC1 (5um) Type III, Colorless

|

|

CAD Supplier

|

N/A

PennEngineering® (PEM®)

|