Catalog

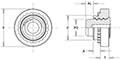

Self-clinching nuts are installed by placing them in properly sized holes in sheets and applying a parallel squeezing force to the head of the nut. The sheet metal surrounding the head cold flows into an undercut thereby making the fastener an integral part of the sheet. A serrated clinching ring prevents the fastener from rotating after installation.

Provide load-bearing threads in thin sheets with high pushout and torque-out resistance.

Type CLA is recommended for use in steel or aluminum sheets HRB (Rockwell "B" scale) 50 or less and HB (Hardness Brinell) 82 or less.

Types CLS / CLSS are recommended for use in steel or aluminum sheets HRB (Rockwell "B" scale) 70 or less and HB (Hardness Brinell) 125 or less.

Types S / SS are recommended for use in steel or aluminum sheets HRB (Rockwell "B" scale) 80 or less and HB (Hardness Brinell) 150 or less.

Type SP is recommended for use in stainless steel sheets HRB (Rockwell "B" scale) 90 or less and HB (Hardness Brinell) 185 or less.

| Items |

S-256-0ZI Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified |

S-256-1ZI Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified |

S-256-2ZI Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified |

S-256-0ZC Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified |

S-256-1ZC Self-Clinching Nuts - Types S, SS, CLS, CLSS, SP - Unified |

|||||

| Description |

N/A

Type S, SS, CLS, and CLSS nuts provide load-bearing threads in thin sheets with high pushout and torque-out resistance. Type SP, PEM 300® nuts provide strong load-bearing threads in stainless steel sheets as thin as .030”. Types S / SS are recommended for use in steel or aluminum sheets HRB (Rockwell "B" scale) 80 or less and HB (Hardness Brinell) 150 or less. Type SP is recommended for use in stainless steel sheets HRB (Rockwell "B" scale) 90 or less and HB (Hardness Brinell) 185 or less. |

|||||||||

| Thread Size | N/A .086-56 (#2-56) | |||||||||

| Thread Code | N/A 256 | |||||||||

| Shank Code | N/A 0 | N/A 1 | N/A 2 | N/A 0 | N/A 1 | |||||

|

A (Shank) Max. |

N/A

.030 in

|

N/A

0.038 in

|

N/A

.054 in

|

N/A

.030 in

|

N/A

0.038 in

|

|||||

| Rec. Min. Sheet Thickness1 | N/A .030 in | N/A .040 in | N/A .056 in | N/A .030 in | N/A .040 in | |||||

| Hole Size in Sheet + .003 - .000 | N/A .166 in | |||||||||

| C Max. | N/A .165 in | |||||||||

| E ± .010 | N/A .250 in | |||||||||

| T ± .010 | N/A .070 in | |||||||||

| Min. Dist. Hole C/L to Edge2 | N/A .19 in | |||||||||

| For Use in Sheet Hardness3 | N/A HRB 80 / HB 150 or Less | |||||||||

| Thread Specification | N/A Internal, ASME B1.1, 2B | |||||||||

| Fastener Material | N/A Heat-Treated Carbon Steel | |||||||||

| Standard Finish | N/A Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless | N/A Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless | N/A Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless | N/A | N/A | |||||

| Optional Finish | N/A | N/A | N/A | N/A Zinc plated per ASTM B633, SC1 (5µm), Type II, yellow | N/A Zinc plated per ASTM B633, SC1 (5µm), Type II, yellow | |||||

| CAD Supplier | N/A PennEngineering® (PEM®) | |||||||||

| Thread Masking Plugs | N/A None | |||||||||

|

||||||||||