Catalog

CAD (0)

▾

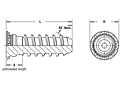

PEM® self-clinching, flush-head studs with X-Press™ threads are typically used with push-on or other plastic fasteners. The coarse thread design of the thread reduces assembly time and provides high retention force.

These self-clinching studs are installed in metal sheets by pressing them into place with any standard press. They can also be installed using automated equipment during the in-die process.

PEM® studs with X-Press™ threads are available with 5 mm and 6 mm metric threads. Lengths range from 10 mm to 25 mm.

Features and Benefits

These self-clinching studs are installed in metal sheets by pressing them into place with any standard press. They can also be installed using automated equipment during the in-die process.

PEM® studs with X-Press™ threads are available with 5 mm and 6 mm metric threads. Lengths range from 10 mm to 25 mm.

Features and Benefits

- Offers fast, reliable attachment.

- Reduces assembly time.

- Allows for lighter assembly.

- Self-clinching stud mounts flush in metal sheets as thin as 1mm.

- Thread design accommodates paints and coatings without compromising performance.

- Self-clinching technology is cleaner and has a more attractive finished appearance than welding.

- Can be installed during the stamping process with PEMSERTER® in-die technology.

Unit of Measure