Catalog

CAD (0)

▾

- Installs into thin, harder, high strength steel materials (high strength steel sheets at 975MPA maximum ultimate tensile)

- Allows overall weight reduction for all vehicles

- Provides lower installed cost

- Unplated threads may be oversized sized as permitted by thread standards to accept minimum plating thickness of .00020”/.0051 mm

- Addresses environmental concerns

- Smaller outer diameter

- Lighter weight

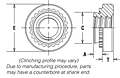

- Flush on reverse side of panel

- Close to edge of panel mounting

- No embossing required

- Hardened nut material provides stronger thread strength

- Can be installed automatically using press or in-die technology

Unit of Measure

- 1 For maximum performance, we recommend that you use the maximum shank length for your sheet thickness.

- 2 HRC - Hardness Rockwell "C" Scale. HB - Hardness Brinell.

- 3 Unplated threads are sized to accept a basic go gauge after .00025 in plating.