Catalog

CAD (0)

▾

Grounding Standoffs - Types SOSG, SOAG - Unified

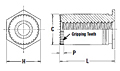

Grounding Standoffs – Types SOAG, SOSG

These standoffs, which use the proven self-clinching design, install with a squeeze in properly sized round holes - and become permanently mounted in the thin sheet.

Types SOAG and SOSG grounding standoffs are designed for clinching into steel or aluminum chassis while the “gripping teeth” on the opposite end of the standoff firmly contact mating PC board.

If you require a standoff which we do not offer in this bulletin, please contact us. We will be happy to work with you to satisfy your special need.

For special lengths greater than .500”, Types SOSG and SOAG are blind threaded.

Types SOAG and SOSG grounding standoffs are designed for clinching into steel or aluminum chassis while the “gripping teeth” on the opposite end of the standoff firmly contact mating PC board.

If you require a standoff which we do not offer in this bulletin, please contact us. We will be happy to work with you to satisfy your special need.

For special lengths greater than .500”, Types SOSG and SOAG are blind threaded.

Unit of Measure

| Items |

SOSG-6440-4 Grounding Standoffs - Types SOSG, SOAG - Unified |

SOSG-6440-6 Grounding Standoffs - Types SOSG, SOAG - Unified |

SOSG-6440-8 Grounding Standoffs - Types SOSG, SOAG - Unified |

SOSG-6440-10 Grounding Standoffs - Types SOSG, SOAG - Unified |

SOSG-6440-12 Grounding Standoffs - Types SOSG, SOAG - Unified |

|||||

| Description |

N/A

These standoffs, which use the proven self-clinching design, install with a squeeze in properly sized round holes - and become permanently mounted in the thin sheet. Types SOAG and SOSG grounding standoffs are designed for clinching into steel or a |

N/A

These standoffs, which use the proven self-clinching design, install with a squeeze in properly sized round holes - and become permanently mounted in the thin sheet. Types SOAG and SOSG grounding standoffs are designed for clinching into steel or aluminum chassis while the “gripping teeth” on the opposite end of the standoff firmly contact mating PC board. If you require a standoff which we do not offer in this bulletin, please contact us. We will be happy to work with you to satisfy your special need. For special lengths greater than .500”, Types SOSG and SOAG are blind threaded. |

N/A

These standoffs, which use the proven self-clinching design, install with a squeeze in properly sized round holes - and become permanently mounted in the thin sheet. Types SOAG and SOSG grounding standoffs are designed for clinching into steel or aluminum chassis while the “gripping teeth” on the opposite end of the standoff firmly contact mating PC board. If you require a standoff which we do not offer in this bulletin, please contact us. We will be happy to work with you to satisfy your special need. For special lengths greater than .500”, Types SOSG and SOAG are blind threaded. |

N/A

These standoffs, which use the proven self-clinching design, install with a squeeze in properly sized round holes - and become permanently mounted in the thin sheet. Types SOAG and SOSG grounding standoffs are designed for clinching into steel or aluminum chassis while the “gripping teeth” on the opposite end of the standoff firmly contact mating PC board. If you require a standoff which we do not offer in this bulletin, please contact us. We will be happy to work with you to satisfy your special need. For special lengths greater than .500”, Types SOSG and SOAG are blind threaded. |

N/A

These standoffs, which use the proven self-clinching design, install with a squeeze in properly sized round holes - and become permanently mounted in the thin sheet. Types SOAG and SOSG grounding standoffs are designed for clinching into steel or aluminum chassis while the “gripping teeth” on the opposite end of the standoff firmly contact mating PC board. If you require a standoff which we do not offer in this bulletin, please contact us. We will be happy to work with you to satisfy your special need. For special lengths greater than .500”, Types SOSG and SOAG are blind threaded. |

|||||

| Thread Size | N/A .112-40 (#4-40) | |||||||||

| Thread Code | N/A 6440 | |||||||||

| Length Code | N/A 4 | N/A 6 | N/A 8 | N/A 10 | N/A 12 | |||||

| Min. Sheet Thickness | N/A .040 in | |||||||||

| Hole Size in Sheet + .003 - .000 | N/A .213 in | |||||||||

|

C + .000 - .005 |

N/A

.212 in

|

|||||||||

| H ± .005 | N/A .250 in | |||||||||

| L - Length + .010 –.0001 | N/A .125 in | N/A .187 in | N/A .250 in | N/A .312 in | N/A .375 in | |||||

| P Nom. | N/A .030 in | |||||||||

| Anvil Hole Diameter + .003 -.000 | N/A .216 in | |||||||||

| Min. Dist. Hole C/L to Edge | N/A .27 in | |||||||||

| For Use in Sheet Hardness2 | N/A HRB 70 / HB 125 or Less | |||||||||

| Thread Specification | N/A Internal, ANSI B1.1, 2B | |||||||||

| Fastener Material | N/A 300 Series Stainless Steel | |||||||||

| Standard Finish | N/A Passivated and/or Tested Per ASTM A380 | |||||||||

| CAD Supplier | N/A PennEngineering® (PEM®) | |||||||||

|

||||||||||